Troubleshooting for End Milling

| # | Failure | Cause | Countermeasures |

|---|---|---|---|

| Cutting Edge Failure | |||

| 1 | Excessive Wear | Cutting Conditions • Cutting speed is too fast • Feed rate is too large |

• Decrease cutting speed and feed rate |

| Tool Shape • The flank relief angle is too small |

• Change to an appropriate flank relief angle | ||

| Tool Material • Insufficient wear resistance |

• Select a more wear-resistant substrate • Use a coated tool |

||

| 2 | Chipping | Cutting Conditions • Feed rate is too large • Depth of cut is too large • Tool overhang is too long |

• Decrease cutting speed • Reduce depth of cut • Adjust tool overhang to the correct length |

| Machine Area • Workpiece clamping is too weak • Tool mounting is unstable |

• Clamp the workpiece firmly • Make sure the tool is seated in the chuck properly |

||

| 3 | Fracture | Cutting Conditions • Feed rate is too large • Depth of cut is too large • Tool overhang is too long • Cutting edge is too long |

• Decrease cutting speed • Reduce depth of cut • Reduce tool overhang as much as possible • Select a tool with a shorter cutting edge |

| Tool Shape • Web thickness is too small |

• Change to more appropriate web thickness | ||

| Others | |||

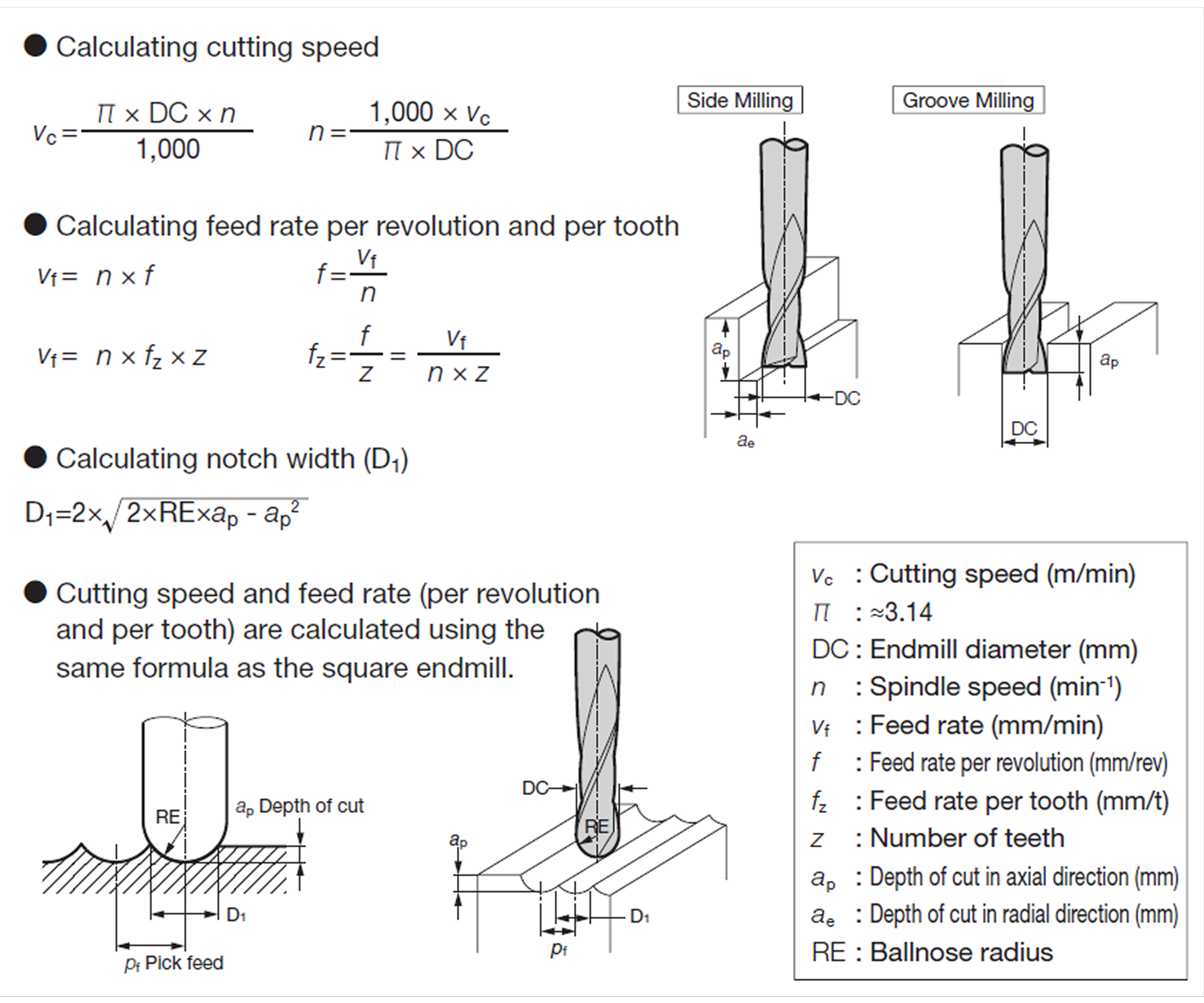

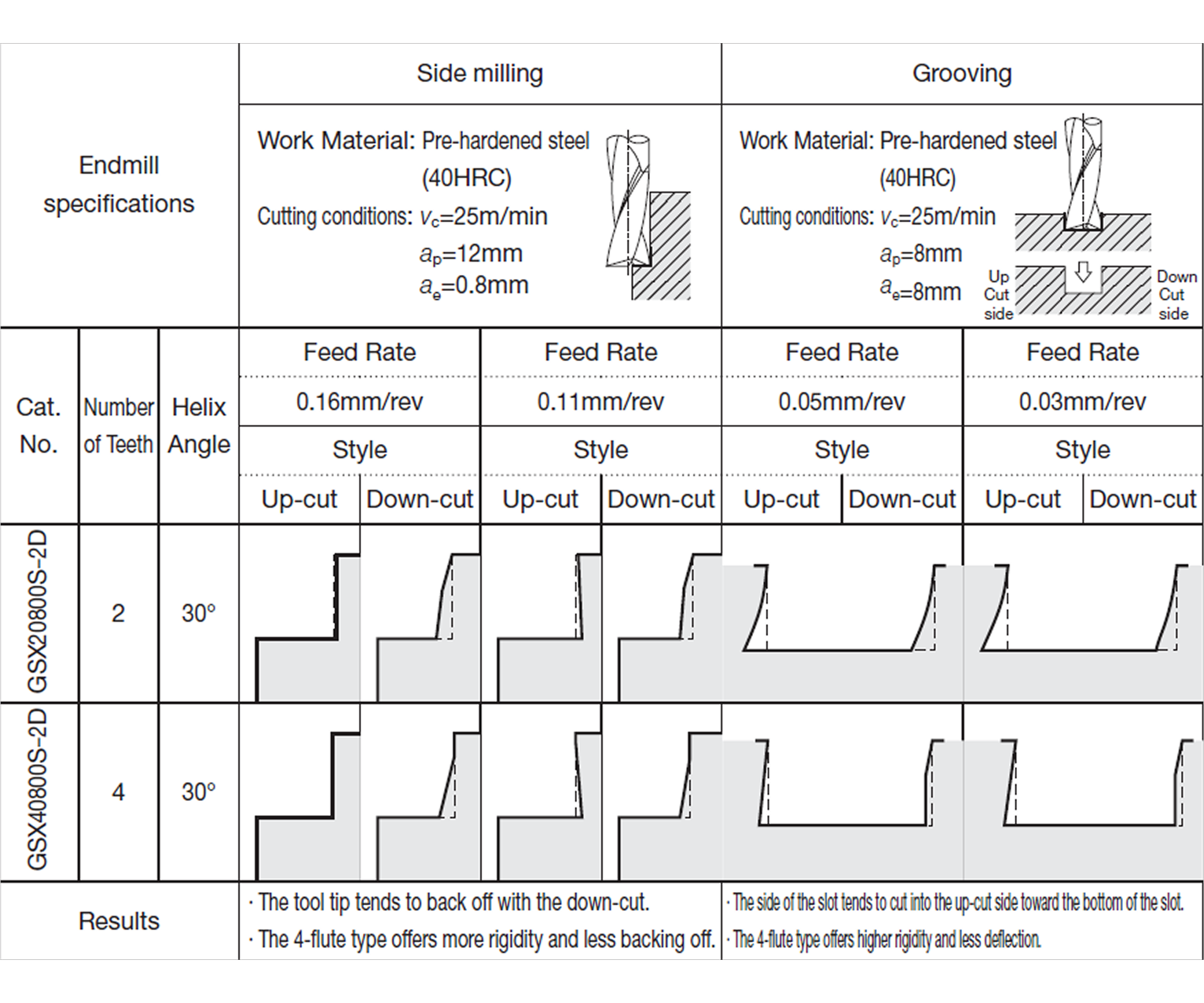

| 1 | Deflection in Wall Surface | Cutting Conditions • Feed rate is too large • Depth of cut is too large • Tool overhang is too long • Cutting on the down-cut |

• Decrease cutting speed • Reduce depth of cut • Adjust tool overhang to the correct length • Change direction to up-cut |

| Tool Shape • Helix angle is too large • Web thickness is too small |

• Use a tool with a smaller helix angle • Use a tool with the appropriate web thickness |

||

| 2 | Unsatisfactory Machined Surface Finish | Cutting Conditions • Feed rate is too large • Chip biting |

• Decrease cutting speed • Use air blow • Use an insert with a larger relief pocket |

| 3 | Chattering | Cutting Conditions • Cutting speed is too fast • Cutting on the up-cut • Tool overhang is too long |

• Decrease the cutting speed • Change direction to down-cut • Adjust tool overhang to the correct length |

| Tool Shape • Rake angle is too large |

• Use a tool with an appropriate rake angle | ||

| Machine Area • Workpiece clamping is too weak • Tool mounting is unstable |

• Clamp the workpiece firmly • Make sure the tool is seated in the chuck properly |

||

| 4 | Chip Blockage | Cutting Conditions • Feed rate is too large • Depth of cut is too large |

• Decrease cutting speed • Reduce depth of cut |

| Tool Shape • Too many teeth • Chip biting |

• Reduce number of teeth • Use air blow |

||